Let’s start with a disclaimer: I am a hobbyist. I do electronics mainly for fun, occasionally for serious business. All my thoughts are related to the context of single-person hobbyist (such as me) or a small group of hobbyist/semi-professionals such as RobotikaBrno. What I state here, might not be useful for the professionals.

Recent experience with Kitnic made me think again about component management in my projects – choosing, buying, storing and using electronic components. Before I present my idea, let me briefly describe my workflow.

My Current Workflow

Let’s start in the middle; as you could read in my previous posts I store my components in following manner:

- I have a basic set of 0603, 0805 and 1206 resistors and capacitors in a special boxes (roughly 50 pieces per value).

- ICs like MCUs and various sensor are stored in a grid of small boxes with labels.

- Boards, china modules, etc. are stored in several paper boxes.

- All the other components are in plastic bags with a hand-written label. These bags are kept in groups like transistors, diodes, LEDs, etc…

I also think it a good idea to have some parts on stock. I think everyone is familiar with the situation, when you are making a quick fix and you miss the resistor of the proper value. Ordering a component is time consuming (it takes few days to arrive) and costly (there are the shipping costs).

When I design a board I usually draw a schematics with respect to BOM and my home supplies. That means for example, if a value of a resistor is not critical, I try to match it to one of the values I already have in stock. But I do it only based on what I remember as going through the bags is time consuming. This also works only for my current stock, the stock might be different in a year.

I don’t use BOMs with precise order codes as I am a hobbyist, who populates boards manually and make only 1-5 pcs of a board. I have to care about minimal order quantity and I wonder why are there such a big price differences in practically identical components. When I need to order a component, I generate the BOM for several projects and go through the supplier website finding a component to match my needs with respect to price. I also try to match the components between projects. I don’t care much if I receive my components in reel, tape or a bag (precise order code usually forces me to buy a given packing, which can be in low quantities expensive). The process of ordering components is slow and annoying.

Also there is always a problem to decide what to order and what not to order. I usually base my decisions on my poor memory – I often don’t remember exact quantities I have on stock (and I am lazy to go through it). Therefore I rarely miss a component and usually order something I already have on stock. Also sometimes I order components for a project, which is for some reason left unfinished. Therefore my stock is constantly growing and contains components I will never use again (in my current workflow).

To sum it up – it is a little bit messy. From my experience, I am not the only one having this issue. Even some small companies have it.

What Would Make My Life Easier?

All these problems boil down to common source – component specification. When you use a component in a schematics, you should specify it. People use two methods:

- They supply the part value (resistance, capacity, voltage etc.) and sometimes they add other criteria (e.g. power rating of a resistor).

- Or they supply precise part name or event an order code for a supplier of their selection.

The second method might work for large companies producing thousands of boards – it is easy to order the components and the designer has everything about the components under control. It is also a good way to go with ICs and special components on hobbyist boards. However, when it comes to passives as resistors, capacitors, coils, etc., it does not work well for the hobbyist. If you specify the order code, then it is hard to use your stock supplies. If you decide to stick with a single type of your resistors or capacitors for the stock, it can get quite pricy, as you cannot buy the cheaper alternative. Also if you decide to build a board designed by someone else, you either have to match you stock supply with the order codes on the board or order components specifically for the board.

Let’s take it to the extremes to illustrate my point; when I have a small toy board, I don’t care whether a pull-up resistor is 10k or 12k. I want to specify it to be in range 8k-15k, in 0603 package and power rating greater than 0.05W. Nothing else, like manufacturer, height of the package doesn’t bother me. And any component fulfilling this specification will work for me. The same with capacitors – I usually need a given capacity, least voltage rating, package and min/max ESR and nothing else (like dielectric material) doesn’t bother me a lot in many cases.

The previous paragraph was rather extreme. Usually what I aim for is to make following step easy and repeatable for different settings: “I need an order code for the cheapest resistor with this value, at least this power ratig and with a tolerance at least 5%”. And ideally make the procedure automated based on schematics and allow for merging of BOMs and their simplification (e.g. I can replace 5% resistors with 1% resistors).

Let’s be honest – I think many hobbyist does exactly the same thing when order components for their designs. They do this matching by hand. And it can be a source of bugs as the specification isn’t written anywhere – especially if you are not the author of the board and you don’t know what parameters are critical. Well, it is usually enough that you order for a board designed a year ago.

Therefore I would like to keep track of this specification in schematics. I would like to attach attributes with the specification in KiCAD; like “resistance > 10k && resistance < 12k", "package ~= (0402|0603)". Then I could use an automated tool, leveraging for example Octopart, to find a part matching my criteria. Of course, if something needs to be precise, I put precise specification for the component.

Having this option would also motivate me to store my components in bags/boxes with a sequential numbers and the precise part name and keep an electronic track of my components. Then I could just export this “smart BOM”, verify it against my database and find out, that I should use 100n capacitors from bag nr. 42 and the remaining two capacitors can be taken from a bag nr. 87 (as they probably differ in voltage rating, but I don’t have enough of the first variant). This would force me to reuse most of my stock material and I would by only the necessary things.

It would also ease the situation when I need to find an alternative for a component as I miss one component and I prefer to buy it from a local seller to save time. But the seller does not have the precise component. Given the specification, I know which parameters of the component are crucial, and which not as much. The same case is the situation when I want to build someone else’s board and use as much stock material, as possible.

The Tools

I am not aware any of any ECAD program out there, which would support such a specification of components. Is there something out there I miss? Even a third party service I am not aware of? Do you see any flaws in the component parameter specification? If so, please let me know!

For me the outcome is: This can be easily added to existing tools like KiCAD and Eagle – both of them support attributes. What is needed is a format of these attributes to specify the constraints. Then we can easily build tools on top of it, which will make our life easier.

Recent news: My open letter to the 3D-printing community

I love the 3D-printing community, but I think there is room for improvement. Let's get better in 2023! Read the full letter.

Support my work!

If you like my work (these blog posts, my software and CAD models) and you would like to see more posts on various topics coming, consider supporting me in various ways:

- You can become my sponsor on Github.

- If you prefer, you can also become my Patreon.

- You can buy me a coffee on Ko-fi,

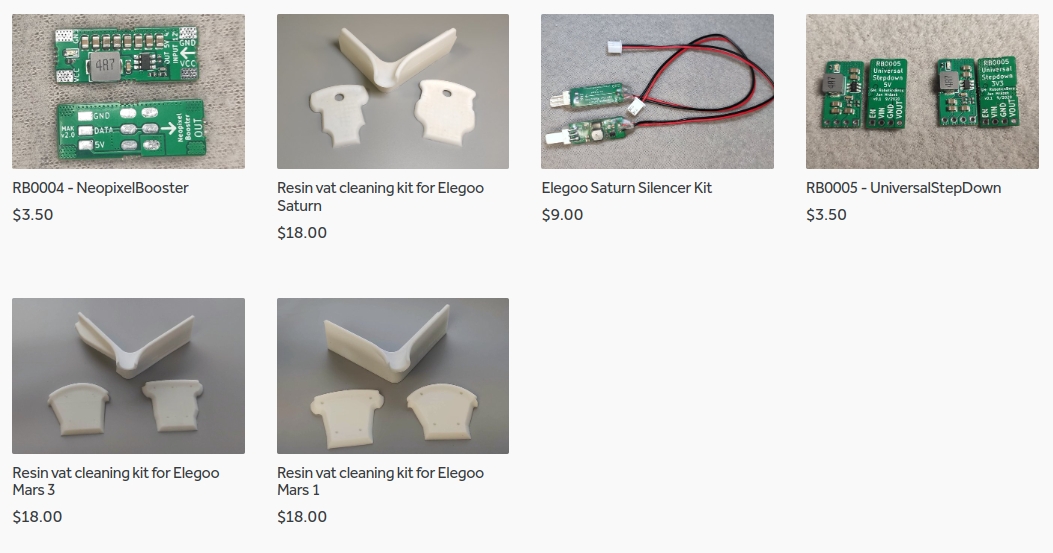

- or you can buy something from my Tindie store (also see below),

- Or you can just share my work!

If you are interested in knowing what I am up to and recent sneak-peaks, consider following me on social media (Twitter, Instagram, Facebook).

My store offers

I launched new tank cleaning kits for Elegoo Saturn, Saturn S, Mars 1, and Mars 3. You can find them in my store.

Thanks for mentioning kitnic.it, it’s an interesting issue for sure and I have been trying to come up with solutions that will let people work together on designs without all these generic little components getting in the way. I blogged about it in a guest blog for Octopart actually.

https://blog.octopart.com/archives/2016/11/kitnic-1-click-bom-cpl

The problem with the feature shown there, the auto-complete feature currently present in 1-click BOM, is that it’s a bit like a self driving car with one button “drive” and then it inevitably crashes into the wall.

I am planning to work on a more controlled web driven, but spreadsheet like BOM tool that leverages Octopart and other APis and makes the selection process easier. I started by implementing a better parser for SMD resistor and capacitor descriptions which is actually done by defining a grammar for descriptions like “1uF 0603 1%” and “0805 1k”

https://github.com/monostable/npm-parse-electronic-component.

The thought of value ranges never occurred to me though. I think you could get away with putting in a range into the value field in KiCAD. Not sure what it’s supposed to do with a footprint range once you do the layout though. What you do with it after it’s in your schematic is a much more difficult problem. It may complicate the issue more than it’s worth because at the end of the day the decision has to be made what component to buy and if there is any uncertainty you probably want a human in the loop.

I have probably updated the text a little, while you were reading. The example I put there originally was rather drastical. I think the common use case is “I need the cheapest/fastest available 10k resistor in package 0603 with at least 0.05W power rating and tolerance better than 5%”.

My point is all we probably need is a fixed format for the specification, which can be put in the components attributes, and then processed by external tools. The question is – how it should look like?

Thank you for the links.

I just had to check the source code, but for tolerance 1-click BOM already selects from the CPL ones that are better or equal to the tolerance you specify.

You are right, other sorts of ranges would need a defined syntax before we could start doing that. I’d be up for adding something to the npm-parser-electronic-component though. Then could experiment with letting people add that information in the tools that make will make use of it.

Just come across this blog and I recognise many of the things you mention. I have been using PartKeepr (https://www.partkeepr.org) to manage my parts – this is a FOSS application which runs on a MySQL backend and has a web interface. It seems pretty reliable.

In order to integrate it with my design workflow, I have come up with a script which takes my BOM (from KiCad) and will interrogate my database of parts. It is available at https://github.com/Gasman2014/KC2PK.