Many people report print adhesion problems on the Elegoo Mars build platform. The build platform is sand-blasted anodized aluminum. Some of them report that sanding of the build platform flat helps. I have never experienced adhesion problems; however, I also sanded my build plate to make it perfectly flat which allowed me to print PCB stencils. Since then I face another problem – my prints stick too well and it is sometimes nearly impossible to take them off the build platform undamaged.

I thought; would it be possible to mimic what Prusa on FDM printers do? That is to attach a flexible steel sheet to the bottom of the platform so once you finish the print, you put the sheet down, bend it and get the prints off the build plate easily? I decided to give a shot. Note that this setup is different from other SLA machines, which claim to have a build plate attached via magnets.

So I designed a simple prototype (probably not suitable for long runs). My goals were the following: make it as simple as possible and to avoid irreversible modification of the build platform as currently, you cannot buy a spare one.

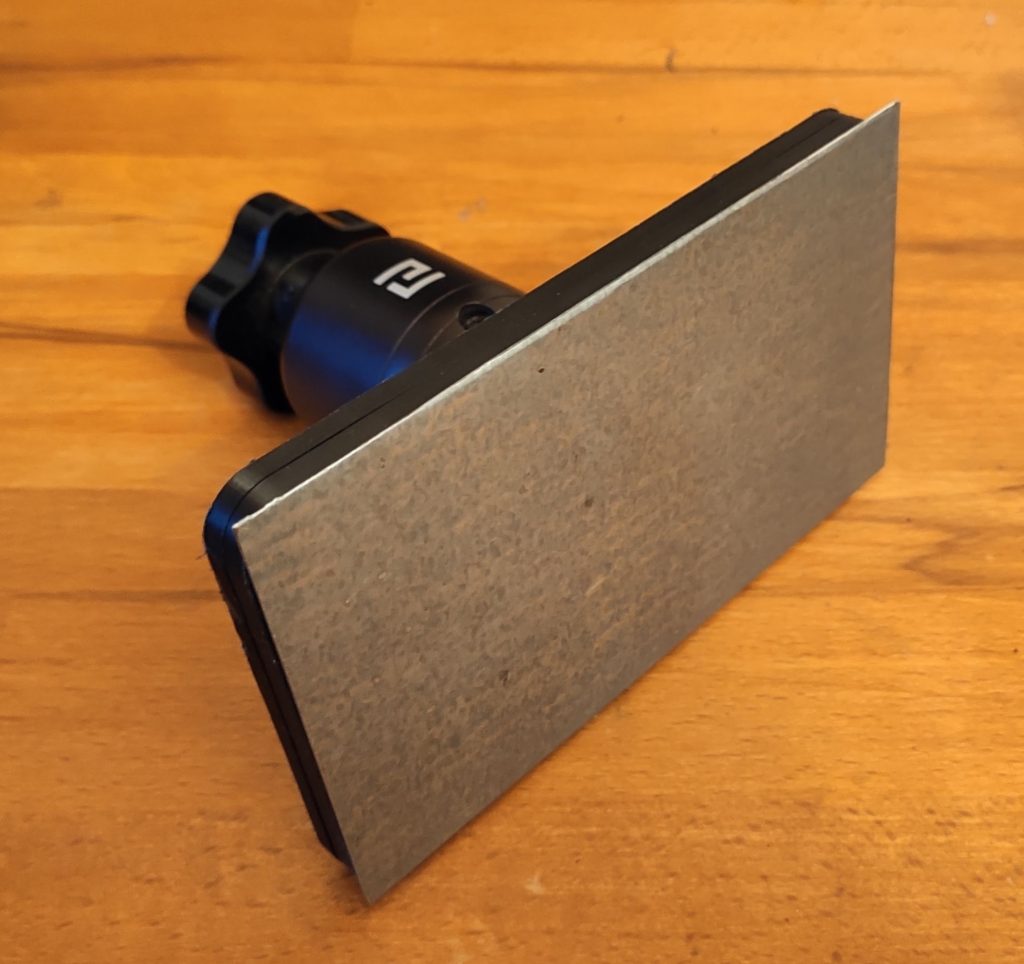

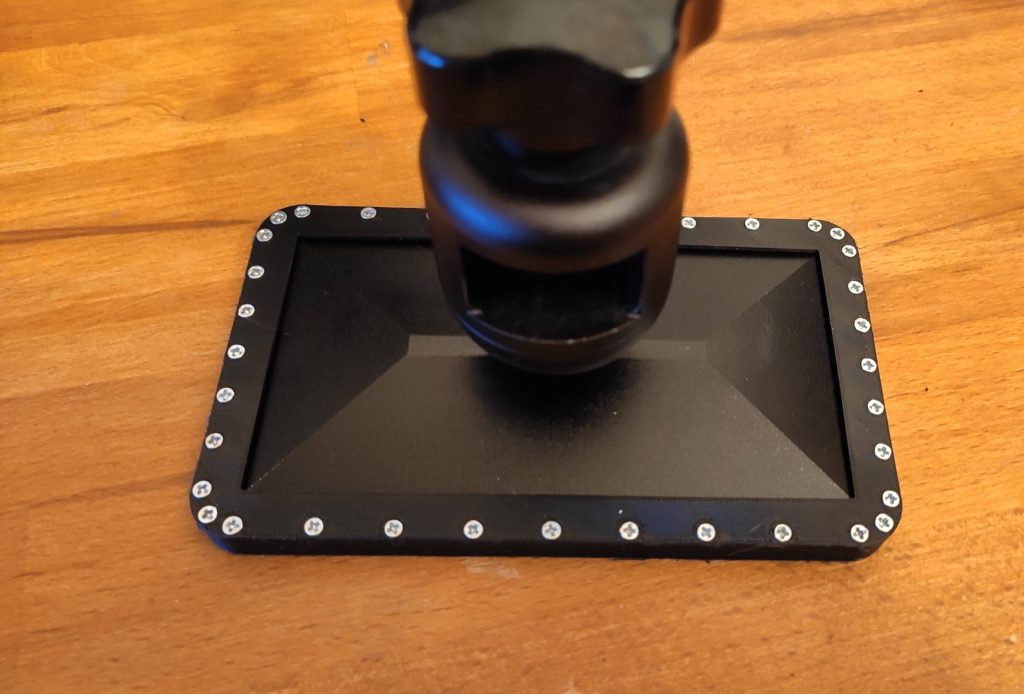

I decided to attach the sheet using neodymium magnets. I designed two simple FDM printed pieces: one plate with pockets for the magnets and one clamp to hold the plate on the bottom of the build plate. You can find my Fusion 360 drawing here.

I put plenty of pockets for magnets as I wasn’t sure how many of them are really necessary to hold the sheet. I have plenty of magnets at home, unfortunately, I accidentally chose a magnet size from which I have only 4 pieces. So it broke my plans with many pockets. But I decided to give it a shot anyway with just 4 magnets. Surprisingly, the 4 magnets hold the sheet quite good (sorry, no precise measurements here). You can find pictures of the assembly below:

I used a 1mm galvanized steel sheet as the sheet – nothing fancy. The sheet is not hardened, therefore it does not act as a spring (can be deformed pretty easily) as you are used from Prusa’s printers. But it’s just a proof of concept. The build plate becomes thicker so I had to lower the Z-axis z-limit switch to be able to level the plate. The plate is designed so it barely fits into the vat.

I did several test prints. All prints were large prints printed directly on the plate – I chose previously prints which I fail to remove from the build plate for the experiment. The results? Subjectively, it helps a lot! The prints come off very easily. Even large, fragile pieces are a piece of cake to remove. Also, event with 4 magnets in the corner the sheet seems to be attached good enough.

This modification opens a lot of possibilities – we can experiment with different surface finishes (e.g., black color, surface roughness, etc). You can also wash the prints with the steel sheet and start printing the next batch immediately.

Note that I do not recommend using this design – it is just a proof of concept. It takes a lot of valuable vat capacity, requires modification of the z-switch trigger, etc. I plan to get a hardened steel sheet (not sure about the proper English term for it – in Czech, we call it “planžeta”) and redesign it to make it more compact and flat. I also consider to machine a new build plate out of aluminum with the pockets for magnets already present.

Did you enjoyed the post? Consider supporting me on Kofi. I use the donations to buy hardware necessary to perform my experiments.

Recent news: My open letter to the 3D-printing community

I love the 3D-printing community, but I think there is room for improvement. Let's get better in 2023! Read the full letter.

Support my work!

If you like my work (these blog posts, my software and CAD models) and you would like to see more posts on various topics coming, consider supporting me in various ways:

- You can become my sponsor on Github.

- If you prefer, you can also become my Patreon.

- You can buy me a coffee on Ko-fi,

- or you can buy something from my Tindie store (also see below),

- Or you can just share my work!

If you are interested in knowing what I am up to and recent sneak-peaks, consider following me on social media (Twitter, Instagram, Facebook).

My store offers

I launched new tank cleaning kits for Elegoo Saturn, Saturn S, Mars 1, and Mars 3. You can find them in my store.

interesting research. this can be indeed usefull

for future reference, a simple, no mod way, to remove stubburn prints is to heat the plate to around 50c with a hairdryer.

i learned this from experience with my sand levelled form1 and ocasionally need to use this method on the photon (Stock anodized plate)

Interesting.

Have you done much research into which surfaces have good adhesion?

I have a build plate mod I want to do, but I don’t want to go through the trial and error of finding something that has the right resin sticktion.

Sadly, my use needs it to be material that starts as a liquid that then hardens, like an epoxy or similar. It’s along the same lines as your black 2.0 (was it 3.0?) Experiment, but mixed into the build plate material.

Thanks for doing this experiment, it’s something I’ve been considering as well for a while.