A month ago I experimented with a flexible build plate on Elegoo Mars – see the previous blog post. It gave promising results, so I decided to design it properly.

First of all – why flexible and removable build plate? There are three reasons:

- you can take the sheet off, bend it at peel the prints really easily. No more spatula scraping and breaking prints from fragile materials (I am looking at you, Elegoo Standard!).

- you can quickly change the sheets without the need for multiple build platforms (a platform costs around 30 €, a sheet around 2 €).

- you can chapel and safely experiment with various surface finishes.

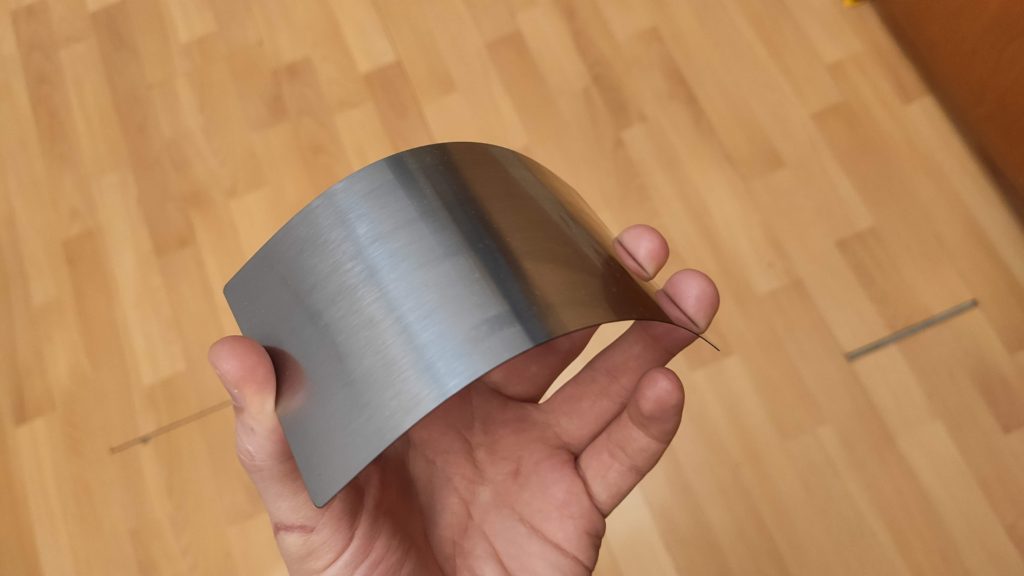

First of all, I used an ordinary galvanized steel sheet in my first experiment. It is really not suited for the task since it is soft and once you bend it stays deformed. The proper choice is the spring steel sheet – it is flat enough and you can bend it as you want. However, since it is hardened steel, you cannot machine it easily. Fortunately, there are companies laser cutting an arbitrary shape out of them on laser or water cutter. The sheets are pretty cheap to make – I made them in a small quantity and depending on the material the price for a single piece was 1-2.5€/piece including shipping. So I made the sheets 2 mm larger than the build platform with a 2mm radius on the corners. This way, there a flange you can press on to remove the sheet from the build plate.

The 0.3mm spring steel sheet

See how flexible it is.

I experimented with different thickness – 1 mm, 0.5 mm, 0.3 mm and 0.2 mm. 1 mm is practically unusable, as it is hard to bend in hand. 0.5 mm is usable, but I prefer much more 0.3 mm. 0.2 mm is my choice for extremely fragile prints.

The second part of the design are the magnets for holding the sheet. They have to be strong enough to not stick away when peeling the layer from the bottom of the vat. Also, you have to mount them on the build plate. First, I bought a self-adhesive magnetic 1mm film. It worked nicely – easy to apply and my biggest fear of the resin dissolving the adhesive showed up false.

The magnetic sheet glued to the build plate

Bottom side of the magnetic sheet

There was however one drawback – the magnetic sheet provided enough adhesion for 1mm and 0.5mm sheets, but not enough for 0.3 and 0.2mm ones. Therefore I started to look for another solution.

I ended up with 20x20x1mm neodymium magnets, which I attached to the build platform via 3M tape. I also oriented the magnets with opposing polarity to force the magnetic flux to close though the steel sheet to get enough adhesion. And it worked – the adhesion of even the thin sheets is sufficient to peel the whole plate covered. See the photos below. There are gaps between the magnets, but I have no trouble with resin being there – the gaps seem to be small enough that the viscous resin doesn’t get deep – only about 8 mm. Which is acceptable. One thing I don’t like about it is the fact that I didn’t get the spacing quite right and it triggers my OCD. Unfortunately, the 3M adhesive is so strong, that I am afraid of breaking the magnets…

To end it, see video below of peeling the prints out of it. One disclaimer – I didn’t was the prints properly, so there is some excess resin (and yeah, I am aware of not having gloves, but small quantities of resin for short period of time does not trigger a reaction for me).

There is, however, one disadvantage of my current solution – the magnetic stirring bar I use for cleaning the prints sticks to the build plate. So I probably need some separator in the tank to use it again.

One observation: my hypothesis I stated in a my previous experiments about surface reflectiveness affecting the size of elephant foot seem to be correct – with the shiny, nearly mirror-like surface I get much larger elephant foot. So the next step will be to coat one the sheets in the dark surface finish – probably by cold bluing the steel sheet.

Recent news: My open letter to the 3D-printing community

I love the 3D-printing community, but I think there is room for improvement. Let's get better in 2023! Read the full letter.

Support my work!

If you like my work (these blog posts, my software and CAD models) and you would like to see more posts on various topics coming, consider supporting me in various ways:

- You can become my sponsor on Github.

- If you prefer, you can also become my Patreon.

- You can buy me a coffee on Ko-fi,

- or you can buy something from my Tindie store (also see below),

- Or you can just share my work!

If you are interested in knowing what I am up to and recent sneak-peaks, consider following me on social media (Twitter, Instagram, Facebook).

My store offers

I launched new tank cleaning kits for Elegoo Saturn, Saturn S, Mars 1, and Mars 3. You can find them in my store.

you should print a base for the build platform and embed the magnets in it during print so they are flush with the surface

I could pour it by epoxy, but it seems there’s no need to…

Just found your blog and I’m hooked with your attempts to squeeze every ounce of performance out of this machine. It also seems with your complete tear down and mods, you’re on the fast track to being able to design a new printer from scratch that massively outperforms the Mars. I’m look forward to more of your hacking or your blueprints for the real Pro version of this machine!!

Can you post a link to where you purchased your spring steel from? I am in the US and the only prices i see are well into the hundreds of dollars just for 2-3 of these things.

I have them custom made by a local company (Czech Republic), so I am not sure if it will help you – https://mepac.cz.

Have you tried recessing just 2 round magnets into the build plate to be flush.

I haven’t – and I am afraid you will need at least 4-5 of them (corners + middle) especially for the thin sheets to prevent from corner peeling and bulging the middle.

Jan,

Thanks for posting your project. I use BuildTak sheets with the same set-up for my FDM printer and agree it is great.

Can you tell me a little more about the steel? There are a lot of different grades of steel and it is not clear which one you are using. From my Internet search – perhaps it is 1095 Blue Tempered Spring Steel?

Thanks for any addition information

– Bruce

I use steel sheets ČSN 1.1274 (it should be DIN C101E).

Jan,

Than you. Fantastic – yes, that is the same as AISI 1095 (a US designation).

Amazon.com has replacement build plates at a reasonable price, so it is possible to recover in case of a catastrophe.

You could cure some resin to fill the gaps.

Awesome; trying to think of reasons why this hasnt been done yet; then again I dont think there is a reason why it hasnt been done on all fdm printer yet either; sometimes someone just has to do the obvious, to get the herd moving, and this seems like one of those cases.

you should print a base for the build platform and embed the magnets in it during print so they are flush with the surface

Hi, I went down this path too before I knew about your endeavors;

Slightly different approach for me – will an FDM rubber flexible sheet combo also work on resin?

TL;DR It does. And all you need is a cutting knife and possibly some sandpaper to smooth the rubber surface a bit.

https://www.youtube.com/watch?v=auuw1Z7MXis

Taková inspirativní stránka blogu!

Ahoj, píšu česky protože anglicky mi moc nejde. Měl jsem originální sadu flexplate s magnetickou gumovou podložku přilepenou páskou 3M. Vše fungovalo hezky dokud jsem nezačal tisknout velké kusy a navíc s různými plochami, větší plochy byly spíše do jedné strany (nešlo to rozdělit jinak). Stalo se, že pří tisku se plech posouval do jedné strany a tisky byly šikmé, dlouho jsem hledal odpověď proč se to děje a nakonec jsem dospěl k názoru že díky rozdělení ploch na jednu stranu, se folie odlepuje postupně z jedné strany na druhé a tak svislý tah Z je nerovnoměrný a plech se postupně posouvá do strany. Doufám že jsem to správně vysvětlil. Zřejmě originální magnetická podložka z gumy je dost slabá, navíc mám tiskárnu s plochou 120×192 mm. Váš nápad dat nedojmové magnety je asi lepší ale, protože uběhlo nějaký čas ptám se jestli funguje pořad dobře a nestane se vám že se při tisku posune?