Recently I got in touch with the customer support of Siraya Tech – my favorite resin brand. I love their Fast Grey resin – it is easy to work with, it is low viscosity resin, which is not brittle. The only downside is that you cannot easily buy it in Europe. I hope it will change soon!

They offered me to test their Tenacious resin – the resin I wanted to try for a long time. You can find a lot about the resin on line. But I wanted to have the first-hand experience.

Tenacious is marketed to be flexible, rubber like with high impact resistance. The exact opposite you are used to with standard resins like Elegoo or Anycubic.

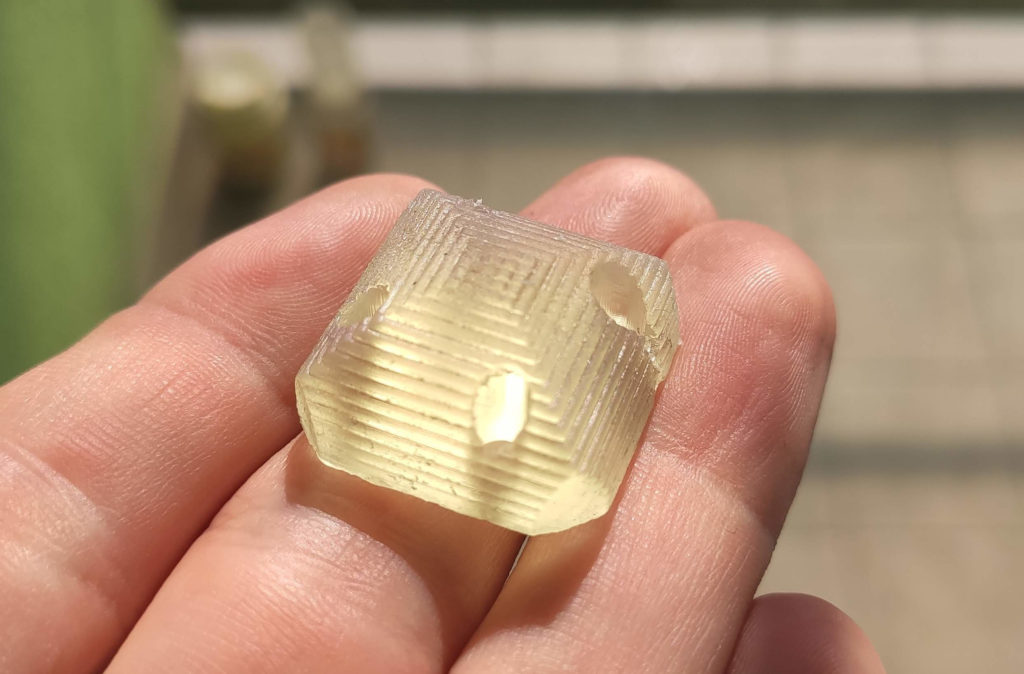

The resin is light yellow and semi-transparent. When you open it, it smells similar to Siraya Blu. The smell isn’t bad – to be honest, I find it quite pleasant. It is is a viscous liquid.

To test it, I decided to print tips of legs for a walking robot. The tips should be soft and provide friction for the legs to not slip on the floor. Since Tenacious is marketed as rubber-like, I thought it could be a suitable option. The resin was easy to print on my Elegoo Mars and the prints came out great. However, I was disappointed with the results. The parts were quite hard and did not provide enough friction. Even when I hollowed them to have a 3mm wall, a 2mm wall, and a 1mm wall they were still too hard for this application. And too slipper. Note that this is not the fault of the resin, rather my mismatched expectations. I revisited all the reviews and videos about tenacious and I found the cause of my mismatched expectations – when you see tenacious prints to be flexible, they are really thin lattice structures. Not beefy pieces.

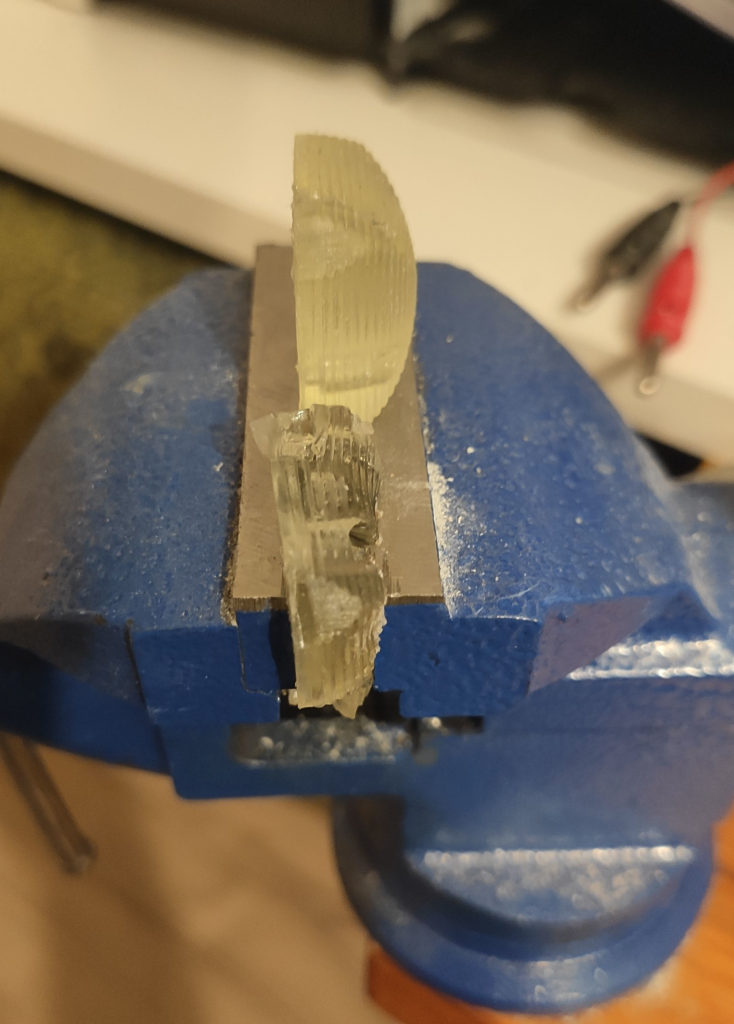

I decided to torture the pieces a little. To my surprise, the pieces are practically undestroyable. You can throw them to ground, smash with a hammer or even put them in a vice and squeeze them to half their original thickness – they do not break! The piece I put into vice stayed deformed, however, after three hours it got back into its original shape.

Compared to FDM printing, do not think about Tenacious like “Flex filament for SLA printers”. No, Tenacious is a tough and ductile material. It is much softer compared to standard resins, but it is not rubbery. It is not hard, but it is not brittle. I would compare it to ABS for FDM printers – it can elongate quite a lot and does not break (like PLA). I will definitely use it for components where I expect high impacts.

I also experimented with adding Tenacious to standard resins like Elegoo Standard. You can read about mixing Tenacious into other resins a lot online. So there is no point in rewriting it – I can confirm that adding 5-20% (by weight) of Tenacious to Elegoo Standard makes a huge difference. The resin is not as brittle – I would compare it to Siraya Fast. This makes a huge difference when you print large objects directly on the build plate. With Elegoo Standard, it is quite challenging to remove them in a single piece. Either they don’t survive the impact of a spatula or they break in half when you put the spatula beneath them. With the 10% of Tenacious, it is still hard to remove them (they stick like hell), but when you are finished you end up with a single piece – no more shattering. The resulting mixture is cheaper than Siraya Fast, however, in my opinion, it cannot replace Fast. Fast is less viscous and easier to work with.

As I pointed in the previous paragraph, I noted that Tenacious sticks really well to the build plate. This brings me to second use for Tenacious I found.

I have experimented a lot with dying resins to custom colors. Recently, I was printing a large batch (2500 pieces) of board-game tokens in customs colors. I used Elegoo Standard white and put epoxy pigment paste in it. It yields nice colors. Dying resins is really easy – you just have to be careful about two things: mix the pigment really well and don’t put too much in it. When you put too much pigment in it, your prints won’t stick to the build plate and also you can observe layer separation. You can save it by adding more of the base resin or printing thinner layers. Then your prints will come out fine. However, you might not get as vibrant colors as you wish or you get extremely long print times. I guess that the layer separation is caused by the pigment blocking too much UV light, therefore only the bottom part of the layer is cured and the top is left uncured. The uncured resin will not stick to the build plate or the previous layers. Therefore, when you add the base resin, you make the resin more transparent and it prints fine. This probably the reason why black resins are extremely hard to print from.

In this project I wanted to get really vibrant colors, so adding a base resin was something I didn’t want to do. Since I had a bottle of Tenacious and I noted that it sticks really well, I tried to add it to the dyed resin. It helped a lot. In my concrete setup, I mixed a color resin which was hard to print. I divided the resin in half. In one half, I added the base resin, in the second I added Tenacious. I had to add 20 % of the base resin to make it nicely printable. In the second batch, once I added 5 % of Tenacious I started to see an improvement. With 10 % of Tenacious, the results were perfect and every print came out great. What’s the best, Tenacious does not change the color of the resin – the colors are still dark and vibrant. Even when I mixed up to 20 % of Tenacious (the same amount as the base resin in my control sample) the colors were practically unaffected. Unfortunately, I wasn’t able to capture the difference on camera – but trust me, the difference is tremendous when you see the printed tokens in person.

Left one is in person much lighter thank the right one

Left one is in person much lighter thank the right one

Left one is in person much lighter thank the right one

Conclusion

I am glad that I tried Tenacious on my own. It is different than I expected. It is not a resin I will use a lot directly, but definitely, it is a handy resin which I would like to keep at least a bottle in my workshop. I will use it to print durable components or to solve issues with layer separation. I can recommend you the same. It is not the cheapest resin, but I think it is worth the money – especially when you use it as an additive. One bottle will last you for an eternity.

Recent news: My open letter to the 3D-printing community

I love the 3D-printing community, but I think there is room for improvement. Let's get better in 2023! Read the full letter.

Support my work!

If you like my work (these blog posts, my software and CAD models) and you would like to see more posts on various topics coming, consider supporting me in various ways:

- You can become my sponsor on Github.

- If you prefer, you can also become my Patreon.

- You can buy me a coffee on Ko-fi,

- or you can buy something from my Tindie store (also see below),

- Or you can just share my work!

If you are interested in knowing what I am up to and recent sneak-peaks, consider following me on social media (Twitter, Instagram, Facebook).

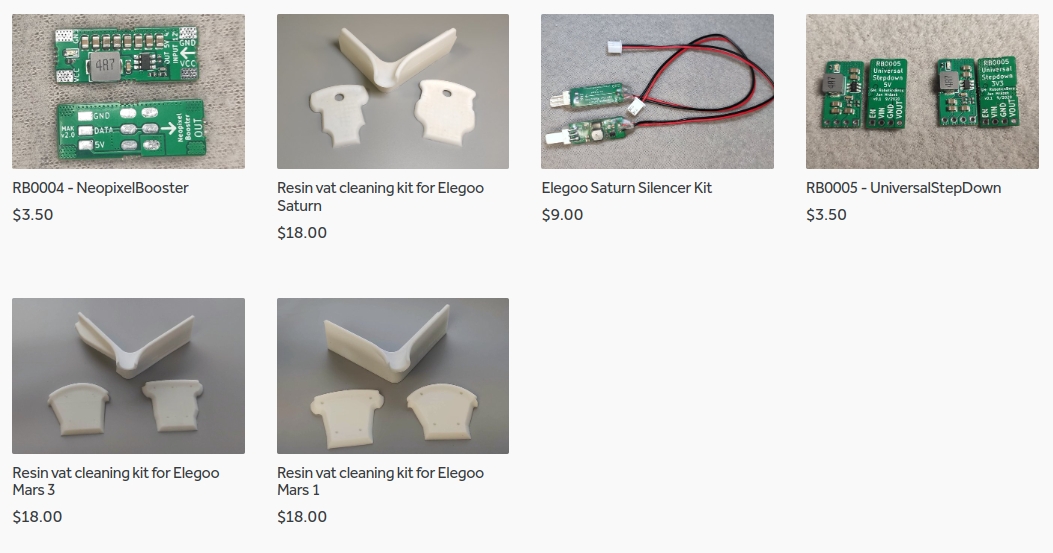

My store offers

I launched new tank cleaning kits for Elegoo Saturn, Saturn S, Mars 1, and Mars 3. You can find them in my store.

Related Posts

- Short Prints and Squished Layers On Chitu-powered Resin Printers: Solution

- Multi-planar Slicing for 3D Printers – For Both FDM and Resin

- Open letter to the 3D printing community: Let’s be better in 2023! What should we do?

- Continuous Printing On LCD Resin Printer: No More Wasted Time On Peeling? Is it possible?

I really want to try this product out for practical props for cosplayy and such; it really seems like the perfect product for it! It’s really sad it doesn’t seem to be available at all really here in Europe, haven’t found any place at all that ships to Sweden so far. Did you find somewhere that actually ships to Europe or have you only gotten a hold of this test bottle they sent?

I have talked to Siraya Tech. They should make their resins available at Amazon.co.uk and Amazon.de within 60 days. However, they weren’t able to specify the price yet. But I guess it will be cheaper than directly importing it from Amazon.com (65 USD/kg + cca 15 USD shipping + 20 USD import duties). If you want to buy it in Europe, try https://3dpartnershop.com/product/siraya-tenacious-1kg/ – I bought Blu there. Tenacious is, however, currently out of stock.

Cool! I’ll keep a lookout on Amazon in the coming months then! Thanks for the reply!

You do realise Siraya Tech are an American company?

I do, why?