Recently, I discovered Resione resins. They have a wide variety of resins. They also have a series of tough and flexible resins. They also have an EU distribution center, so the resin arrives quickly and you don’t have to care about customs. Overall, the resins seemed nice. I might make a separate blog post about their resins in the future.

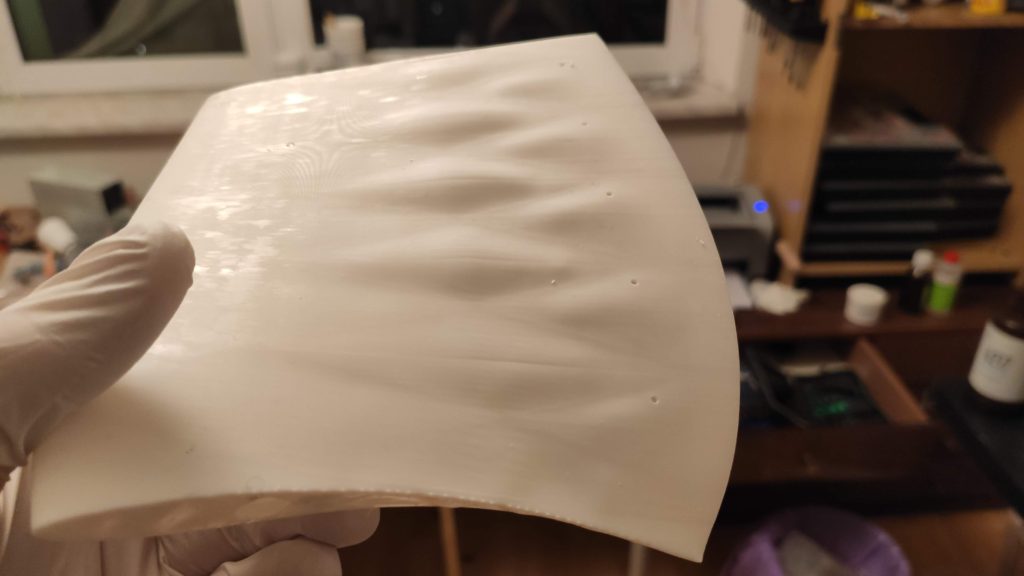

When I was working on a big project (blogpost upcoming, sneak-peaks on my Twitter and Instagram) I decided to use Resione M68 — tough snow-white resin. The parts I printed were thin-wall parts (wall thickness of 0.5–1 mm). They also have a lot of internal cavities where a liquid can be trapped. After printing, the pieces looked great! However, it was a rainy day and the air humidity increased up to 80 %. The next day I found my parts deformed like this:

Parts after 24-48 hours in high humidity

Parts after 24-48 hours in high humidity

I soaked one of the parts for 20 hours in water. This happened.

It seems that the Resione M68 absorbs a lot of moisture and the large flat areas between infill of the component expand, thus they form bumps. So I took one piece and soaked it into the water for 20 hours and it even cracked.

It is a well-known phenomenon, that some plastics absorb moisture. There is even an ISO standard 15512:2019 for measuring this (which I don’t have access to, unfortunately). Since my components will be exposed to the weather condition, I decided to make an experiment to determine which resins would be suitable and which not.

The experiment

Unfortunatelly, I cannot follow the ISO 15512 as I don’t have access to it. Therefore, I designed a custom experiment.

Note that this experiment is designed to only compare the resins, it is not designed to get precise values. For having precise values I miss proper measuring equipment and a controlled environment. So please, when I give you some numbers don’t take them for granted. There might be a lot of errors here!

The general procedure is: take a test sample, dry it out, measure its weight. Then, soak it in water, dry it and wight again. The percentage difference in weight will give us the amount of water absorbed.

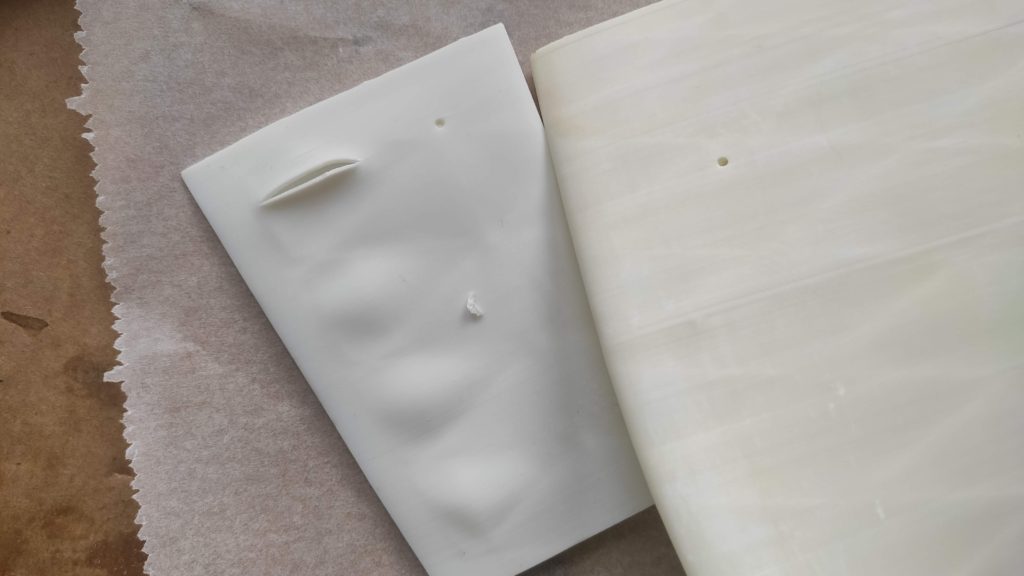

First, we need a test sample. I created the following piece:

Why such shape, you ask? I wasn’t sure how precisely I would be able to measure the weight, therefore I included a thin sheet of material stretched between a rigid frame. If it soaks waters and expands, it will form a bump. I included three thicknesses of the sheet – 0.3, 0.5 and 1 mm. I also wanted the piece to printed flat on the bed, therefore I angled the sheet so it can be printed without supports. The holes in the bottom serve as a vent holes to prevent model collapsing when printing flat on the build plate. Then I added the grooves on the sides to increase surface area to support moisture absorption.

I printed the samples out of the following materials:

- Resione G217 (transparent)

- Resione M68 (snow-white)

- Prusa Tough (orange)

- Siraya Tech Fast (light gray)

- Siraya Tech Tenacious (yellowish, translucent)

- Siraya Tech Build (smokey black)

- Siraya Tech Blu (blue)

- Epax Hard (black)

- Epax Hard & Tough (dark gray)

- Elegoo Standard (green)

- Elegoo ABS like (white)

All the samples

Samples detail

Samples detail

Samples detail

Samples detail

Samples detail

Samples detail

Samples detail

Samples detail

Samples detail

Samples detail

Then I prepared the samples – I dried them out in 50°C for 12 hours to ideally get all the already captured moisture out. It was surprising for me how much moisture came out – the walls of the drying container got fogged significantly. Then I measured the samples and divided them into 3 groups: 1 will be soked into water in room temperature for 24 hours, the other will be soked in IPA and the third one will be left on the air. Then I dried all samples with cotton towel and blow them with compressed air to remove any drops of liquid. After leaving them of 1 hours to completly dry out, I measured the weight of the samples again.

Results

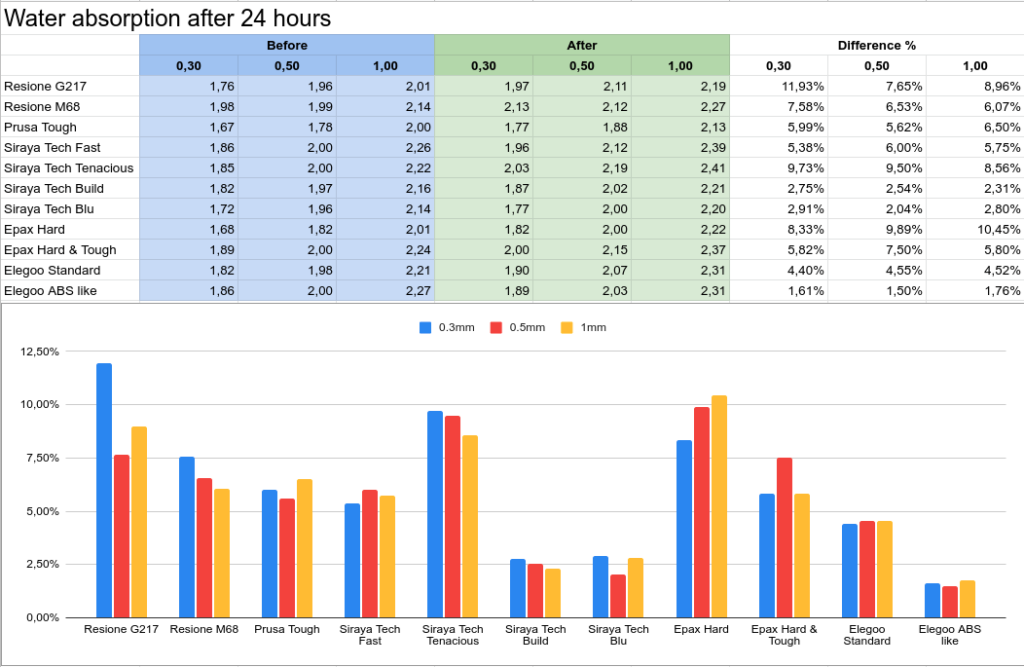

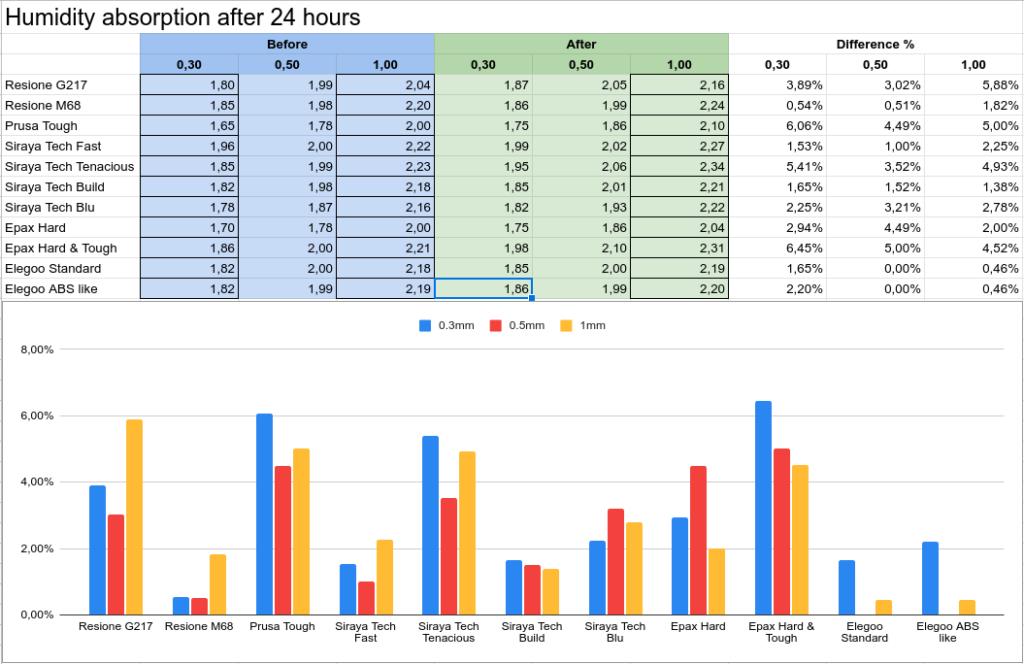

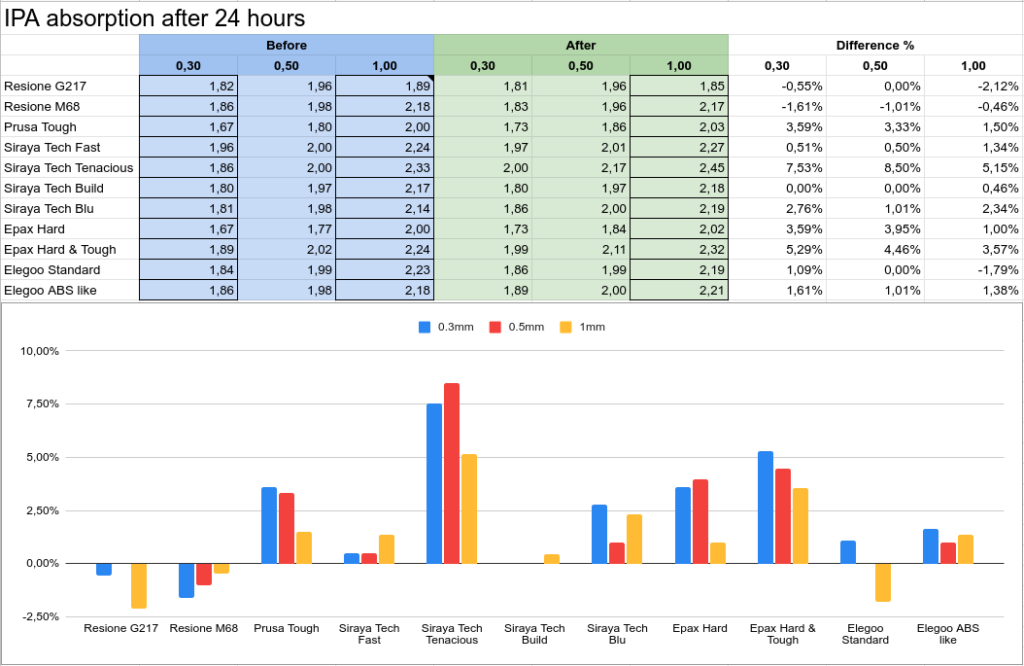

I put the results into tables and plot some charts to illustrate the effects. You can find the charts below.

Note that the weight of the samples is quite small therefore I expect the numbers to be rather imprecise and have a lot of noise in it. Any observations like “This resin in 10% better than that one” might be misleading. I made the experiment only to get a general overview of the resin properties, I wasn’t aiming for precise numbers.

I also took pictures of the samples. Most of them got some bumps on them as expected:

Epax Hard & Tough after 4 hours in water

Epax Hard & Tough after 4 hours in water

Siraya Tech Fast after completed experiment with water

Siraya Tech Fast after completed experiment with water

Epax Hard after 24 hours in water

Prusa Tough after 24 hours in water

Prusa Tough after 24 hours in water

Elegoo ABS-like after 24 hours in water

Elegoo ABS-like after 24 hours in water

Elegoo ABS-like after 24 hours in water

Siraya Tech Build after 24 hours in water

Siraya Tech Build after 24 hours in water

Conclusions

My experiments showed that most of the SLA resins soak water. As I expected, standard (brittle) resins soak a little. Usually the tough resins soak a lot. What I was surprised about is that Elegoo ABS-like soaked very little.

Usually, the resins expand in length once they soak water. This was really notable for Resione M68 and G217, Siraya Tech Fast, Siraya Tech Build, Epax Hard and Hard & Tough. Surprisingly, Siraya Tech Blu, Prusa Tough and Elegoo Standard and ABS-like do not expand much. I was really surprised by the results of Siraya Tech Build – it does not soak a lot, but in the thin cross section it expands a lot (and it did not expand at all for 1mm wall). It seems like it absorbs the moisture slowly, therefore, it does not penetrate much in depth.

Most of the resins didn’t have any notable difference change in the properties. Only Resione M68 and G217, Siraya Tech Tenacious and Epax Hard & Tough become really soft and plastic. It was easy to deform them. Siraya Tech Fast becomes just a little softer.

The process is also reversible – when you dry the resins for several hours at 50°C, they return to their original state.

What I find interesting is that the resisn absorb moisture also from air. Usually, they absorb less than when directly soked in water. Also the material properties do not change. Only Siraya Tech Tenacisous was really hard after being dry and it become a little flexible when exposed to air humidity.

I also tried to soak resins in IPA to see if long exposures to IPA change something or not. The results I got can be interpreted in two ways:

- the resins practically do not soak IPA (and the neagtive values are errors in measurement)

- the resins soak IPA, gain weight but they also dissolve a little so the weight of some samples decreased.

What to take from this post?

The resins absorb moisture and the moisture changes the properties a little (especially dimensional accuracy of thin-walled parts). Think about it when you design your next part. Also, when precise dimensions are required for a short period of time (e.g., silicone molding) you can dry out the resins.

If you know more about the chemistry of resins and you find a flaw in my procedure, please let me know down in the comments! I will be happy to learn more about it.

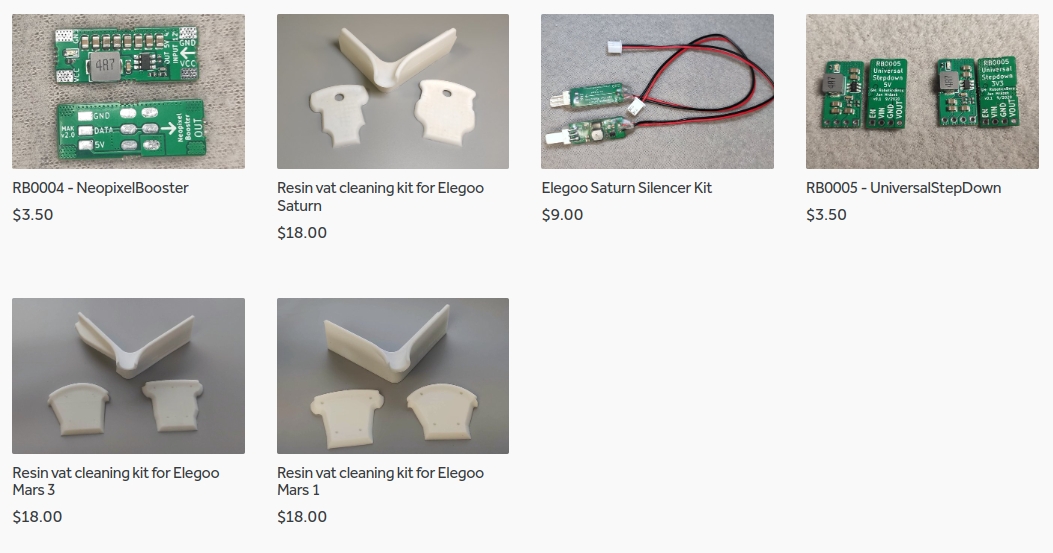

PS: If you like this blog post and you would like to find more posts like this in the future, you can consider supporting me on Ko-fi or buy something from me on my Tindie store.

I also put some work-in progress on my Twitter and Instagram if you are interested in knowing what I am up to.

Recent news: My open letter to the 3D-printing community

I love the 3D-printing community, but I think there is room for improvement. Let's get better in 2023! Read the full letter.

Support my work!

If you like my work (these blog posts, my software and CAD models) and you would like to see more posts on various topics coming, consider supporting me in various ways:

- You can become my sponsor on Github.

- If you prefer, you can also become my Patreon.

- You can buy me a coffee on Ko-fi,

- or you can buy something from my Tindie store (also see below),

- Or you can just share my work!

If you are interested in knowing what I am up to and recent sneak-peaks, consider following me on social media (Twitter, Instagram, Facebook).

My store offers

I launched new tank cleaning kits for Elegoo Saturn, Saturn S, Mars 1, and Mars 3. You can find them in my store.

Related Posts

- Multi-planar Slicing for 3D Printers – For Both FDM and Resin

- Open letter to the 3D printing community: Let’s be better in 2023! What should we do?

- Continuous Printing On LCD Resin Printer: No More Wasted Time On Peeling? Is it possible?

- About the Successful Quest For Perfect MSLA Printer UV Backlight

Awesome!

Have you considered using desiccant beads after you bake at 50C to get even more moisture out?

On the IPA results, if you used high % IPA, it may have dried out the resin even more, because IPA > 70% will actually suck water out of things (like the air, or your skin).

Did you re-dry and remeasure all the samples after the test? You mentioned the IPA lost mass may be due to IPA attacking it and taking some material away, this would help test that.

Personally, I wish you had also tested ST Simple (because I use it a lot), but it’s already known to be hygroscopic and can absorb lots of water.

Thanks for sharing your test and results.

Hello, Jan, I am Jane Liao, a technical engineer of Resione. I have carefully read your recent blogs.

I would like to share with you several points of view.

1. The test criteria for solvent absorption rate are: Percent weight gain over 24 hours for a printed and post-cured 1 x 1 x 1 cm cube immersed in respective solvent,the weighing accuracy is 0.0001g.

2. The deformation of the printed part of M68 resin is probably due to the insufficient curing degree of the newly printed model, which leads to insufficient hardness. At the same time, the model has a hollow structure inside, which may be caused by the residual liquid resin, unclean cleaning or no post-curing, resulting in the deformation of the printed part.

3. Cured resins will not be dissolved by IPA, and most resins will absorb IPA to varying degrees. The reason why M68 and G217 lose weight after soaking IPA may need to be explored from other aspects.

Hope to have more communication with you!

Hello Jane,

thank you for reacting!

1) Which standard does the sample size refers to?

2) The part was printed on Elegoo Saturn, 3s exposure, layer height 0.05 mm. The structure inside allows for a perfect cleaning (there are no enclosed areas – see the CAD model in the post). I washed the internals with IPA via a pump, let it dry out for 24 hours in a dark area, and then curing it for 15-20 minutes under 36W UV light in a 30x30x30 cm chamber (usually all other resins harden within 5 minutes in this setup). So at least the exterior should be cured properly.

Hello Jan,

Thank you for your reply,I will reply to your question as follows:

1. Test standard is ASTM: D570,you can learn about it through Google in detail.

2. The key point is that after cleaning with IPA, the model needs to be blown dry with high pressure air immediately and then cured. Left for 24 hours will cause IPA to corrode the incomplete solidified model.

2. Ok, I usually wipe and blow-dry with pressured air only the outside model. Thanks for the tip. However; I am not sure if in my case that is the reason – the final washing step I used water with soap. But I will definitely design some experiments and test it!

Yes, the last step also needs to be cleaned with clean alcohol or IPA.Do not use water or soap.

Hello Jane,

it took me a while; but I rerun the experiment with the conditions you just described – that is only washing for 15 seconds in IPA, then drying with dry air and then curing. I rerun the experiment with practically identical results. It leads me to conclusion that your resins soak quite a lot of water and then become soft. I think this is not a problem when you know about it – for general use, I love your resins. I just cannot use it for project where the resin come in contact with water (similarly to most of the Siraya Tech resins).

Note, that it is possible that I make a mistake in my workflow. If you think there is a flaw, try printing the test pieces at your lab, properly cure them and send them to me. I would love to be mistaken!

Thank you for this analysis Jan, it helped me alot! I am using my SLA Printer for making very special hose connectors for a prototype for an automatic irrgiation system.

So far, i tested Prusa ABS-like and Prusa Tough. Both are not suitable. Prusa ABS-like gets very soft and breaks immediately after letting it under water for a few hours. On the other hand, Prusa tough does not noticably change when constantly exposed to water (as you mentioned), but it is too brittle. Every time i want to pull of the hose from the printed hose connector, the connector breaks and falls appart. After this experience i had a very hard time to search for a resin that suits my purpose, because datasheets of resins don´t have useful information about water resistance. But i knew i was not going to try another ABS-like resin, until i found your post. I will try Elegoo ABS-like next – whish me good luck. I will keep you updated.

Hi Jan,

What is the best way to PM you? Please kindly advise, thanks. Great effort, man!

There’s a way to contact me at: https://honzamrazek.cz/

Hello, I’m a University student. Is this information published in any type of research paper?

I haven’t written an academic paper on this topic.

I just ran across your post on water absorption of a variety of SLA resins with different wall thicknesses. I own a plating shop in the USA and one of the first things I look at for resins that will be plated is the ASTM D570 water absorption values. Ideally I’d like these to be less than 0.5% weight gain.

We have also developed an internal test to look at water absorption but we use a 1 cm square tube that is 10 cm long and we build these tubes with wall thickness of 0.5, 1, 2 and 3 mm. We test the tubes submersed in water at 38C pulling them at 30 min, 90 min, 180 min and 300 min. to measure weight and length change. The time and temperature is related to the processing conditions for applying a conductive layer on the parts using room temperature electroless nickel and then the initial stages of electroplating in copper. I’d be happy to you some of the results we gotten on Formlabs resins along with a couple of other ones from Sunlu and Arkema. Our tube tests generally track the data on the D570 test. We are looking for suitability of resins for plating and how thin the walls can be before we will have trouble with dimensions.

Hello, could somebody contact me in reference to this subject? I am working with platinum cured Silicone on 3-D printed molds and I really want to get to the bottom of it. I am having a lot of problems obviously with the reaction thank you, Norman McMillan.