Resin 3D printers are awesome, however, the whole process is extremely messy. Especially when an accident happens and the resin leaks from the vat all over the printer.

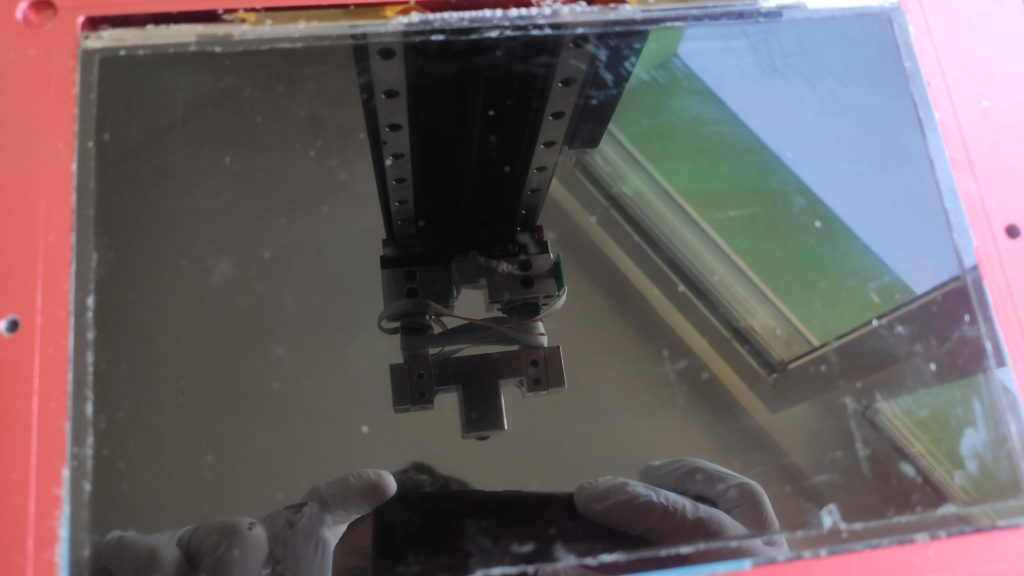

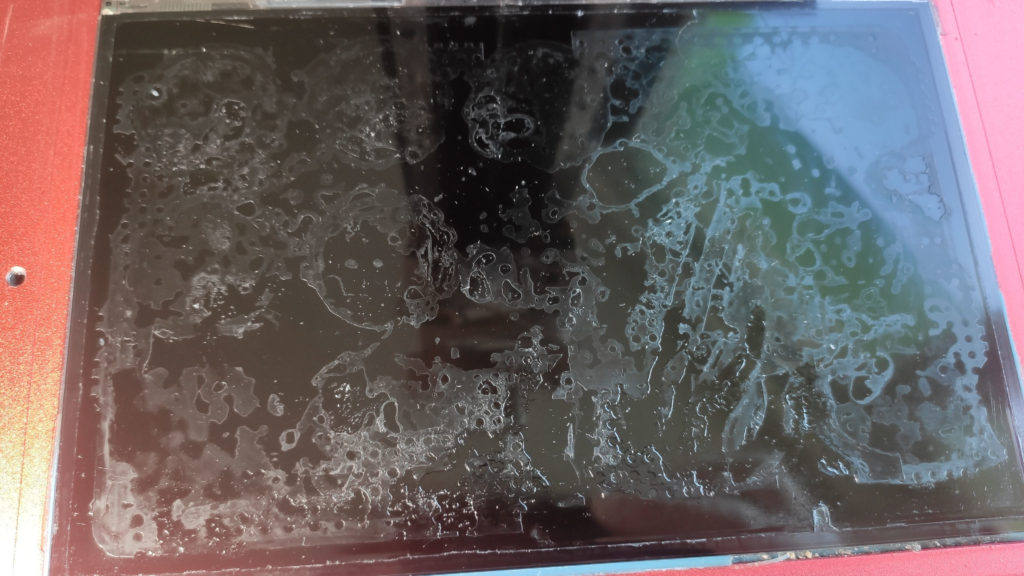

When this happens mid-print, it usually means one thing – the resin will leak onto the precious LCD of the printer and cure. This means one thing – the UV light will be blocked by the cured parts and you will probably experience holes in your printed parts.

Damaged LCD

Damaged LCD

Usually, the people on Facebook advise you to scrape the resin away with a plastic razor. This usually works for small leaks, but it doesn’t work well on large leaks.

I experienced a resin leak recently on my Elegoo Saturn. Scraping the resin was not leading anywhere and I managed to scratch the polarizer film on top of the LCD. Therefore I stopped and I decided to make a (successful experiment): use acetone to dissolve the cured resin. It worked flawlessly!

The method is based on the observation that resin softens in an acetone bath, but the polarizer film seems not to dissolve in acetone.

The procedure

Let me start with a warning – if you decide to follow this guide, you will do it at your own risk. I tested the procedure on the pre-order batch of Elegoo Saturn with the TM089CFSP01 LCD. It is possible that later batches or different LCDs use a polarizer that is not acetone resistant. In that case, the procedure will damage your LCD! If you want to try it, try rubbing a corner of the LCD with acetone first to see if it is acetone resistant or not. On the other hand – if your LCD is ruined with resin, there is nothing you can lose.

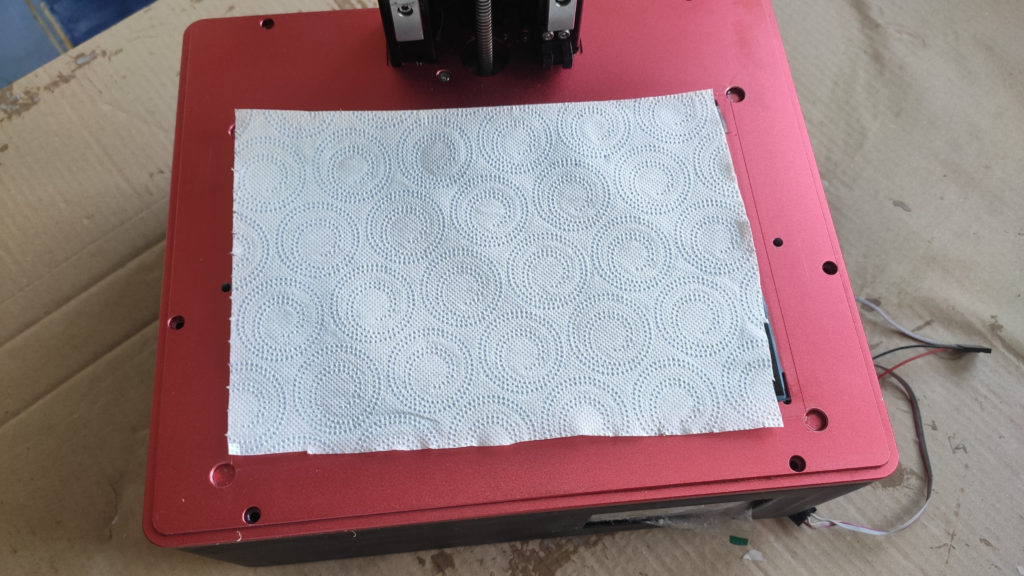

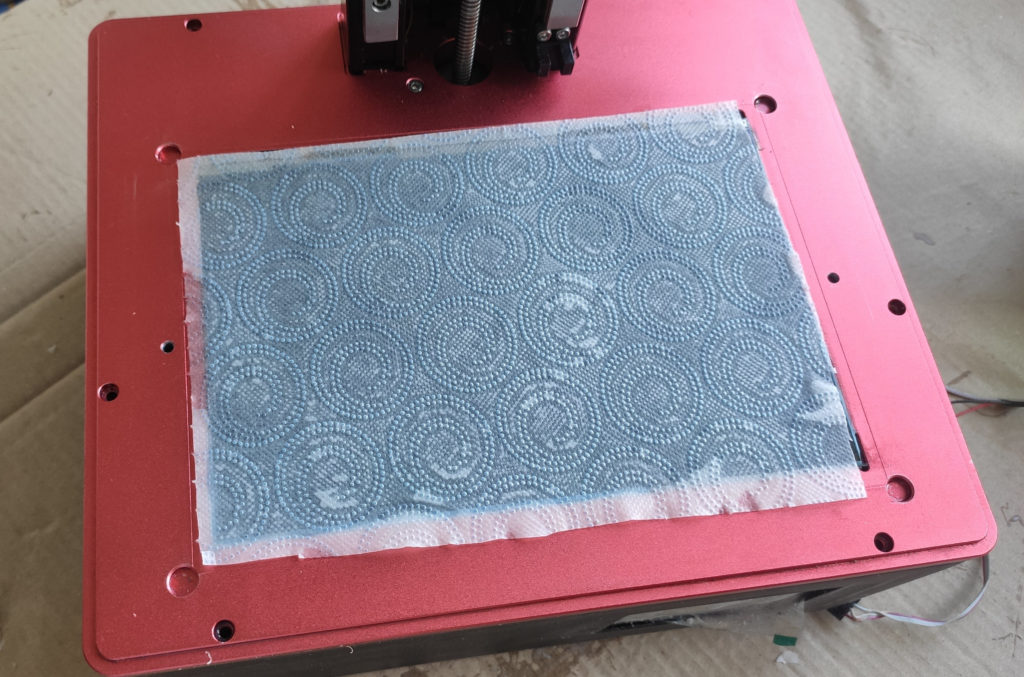

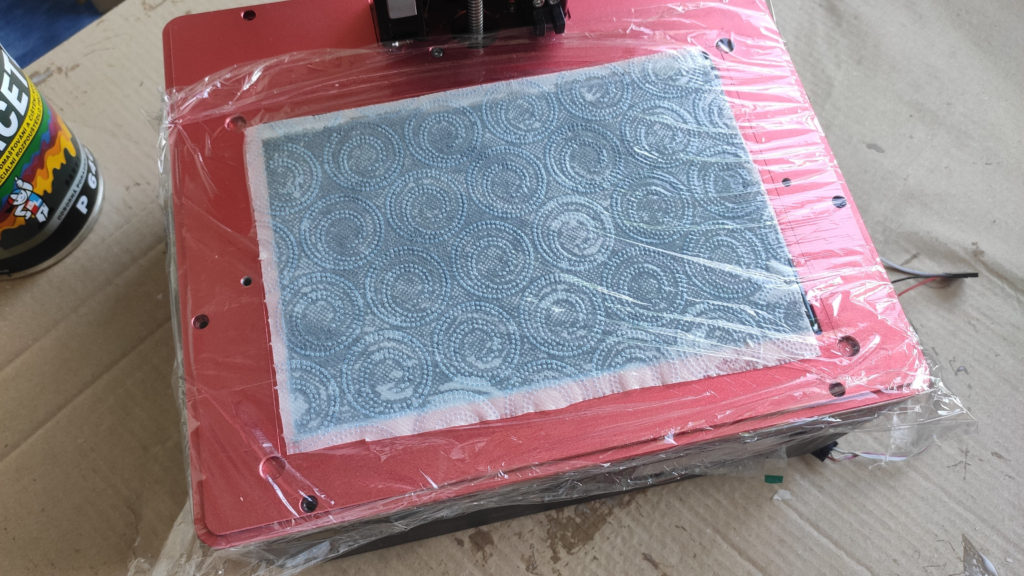

The procedure is simple – soak the cured resin with acetone to soften it and scrape it away. However, the acetone evaporates quickly, so simply pouring it on the screen does not work (as it evaporates), nor rubbing an acetone-wet cloth over it. The solution is to soak a paper towel with acetone, put it on the LCD and cover it with plastic foil to prevent evaporation. After 10-15 minutes the resin softens and is easy to scrape off. You can also apply the same feature with IPA – it will just not make the resin as soft as acetone.

Recent news: My open letter to the 3D-printing community

I love the 3D-printing community, but I think there is room for improvement. Let's get better in 2023! Read the full letter.

Support my work!

If you like my work (these blog posts, my software and CAD models) and you would like to see more posts on various topics coming, consider supporting me in various ways:

- You can become my sponsor on Github.

- If you prefer, you can also become my Patreon.

- You can buy me a coffee on Ko-fi,

- or you can buy something from my Tindie store (also see below),

- Or you can just share my work!

If you are interested in knowing what I am up to and recent sneak-peaks, consider following me on social media (Twitter, Instagram, Facebook).

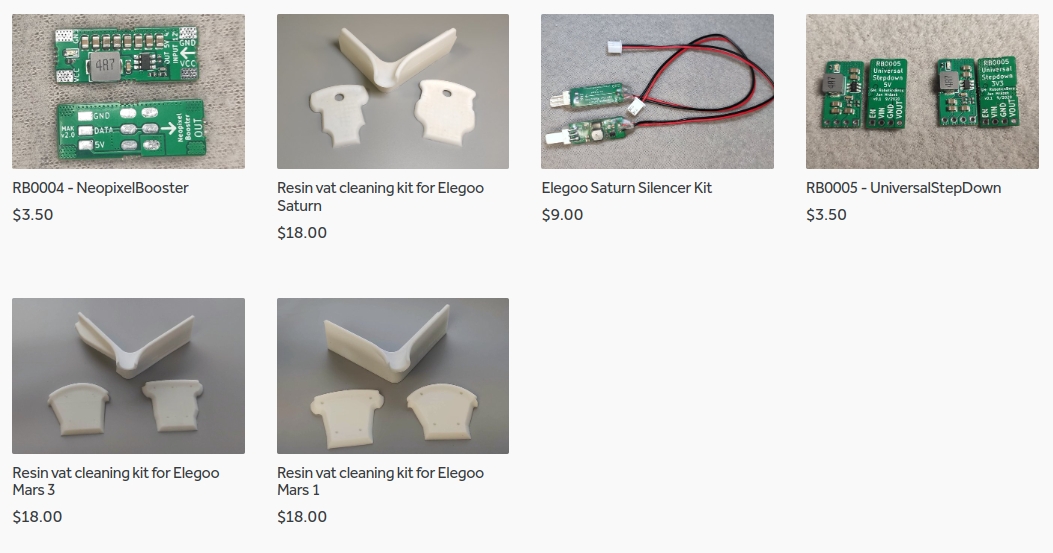

My store offers

I launched new tank cleaning kits for Elegoo Saturn, Saturn S, Mars 1, and Mars 3. You can find them in my store.

Related Posts

- Multi-planar Slicing for 3D Printers – For Both FDM and Resin

- Open letter to the 3D printing community: Let’s be better in 2023! What should we do?

- Continuous Printing On LCD Resin Printer: No More Wasted Time On Peeling? Is it possible?

- About the Successful Quest For Perfect MSLA Printer UV Backlight

I’m glad you put the clear warning on there, as I’ve read at least one account of a polarizer being damaged by Acetone (I don’t remember the printer make/model they had).

Thanks, I just tried this with my Saturn, used nail varnish remover. Works like a charm!

Advising to use a harsh solvent on a very expensive machine is just foolish. Use package tape and be patient.

And what exactly is foolish about it? Did you read the article? There is clear warning. Let me cite it for you:

“Let me start with a warning – if you decide to follow this guide, you will do it at your own risk. I tested the procedure on the pre-order batch of Elegoo Saturn with the TM089CFSP01 LCD. It is possible that later batches or different LCDs use a polarizer that is not acetone resistant. In that case, the procedure will damage your LCD! If you want to try it, try rubbing a corner of the LCD with acetone first to see if it is acetone resistant or not. On the other hand – if your LCD is ruined with resin, there is nothing you can loose.”

I think it is foolish to not give it a last try (at least partially) fix a completely damaged LCD. You have not much to loose! I think it is rather foolish to do nothing and have a non functional machine. And always, use common sense and read carefully.

Does isopropyl alcohol instead of acetone work?

This is also a question I had, can IPA be utilized ?

Yes, it can but it is not as effective. Acetone really makes most of the resin soft.

Does anybody know what’s causing this in the first place? I cant seem to find any leaks and i havent spilt any resin onto the dispay in the first place.

FYI: On the Saturn S, I can say for certain, acetone loosens the adhesives on the tape holding the polarizing film. So BE CAREFUL.